Energy

CONTACT

Diego Fernández

INERCO USABURNERS

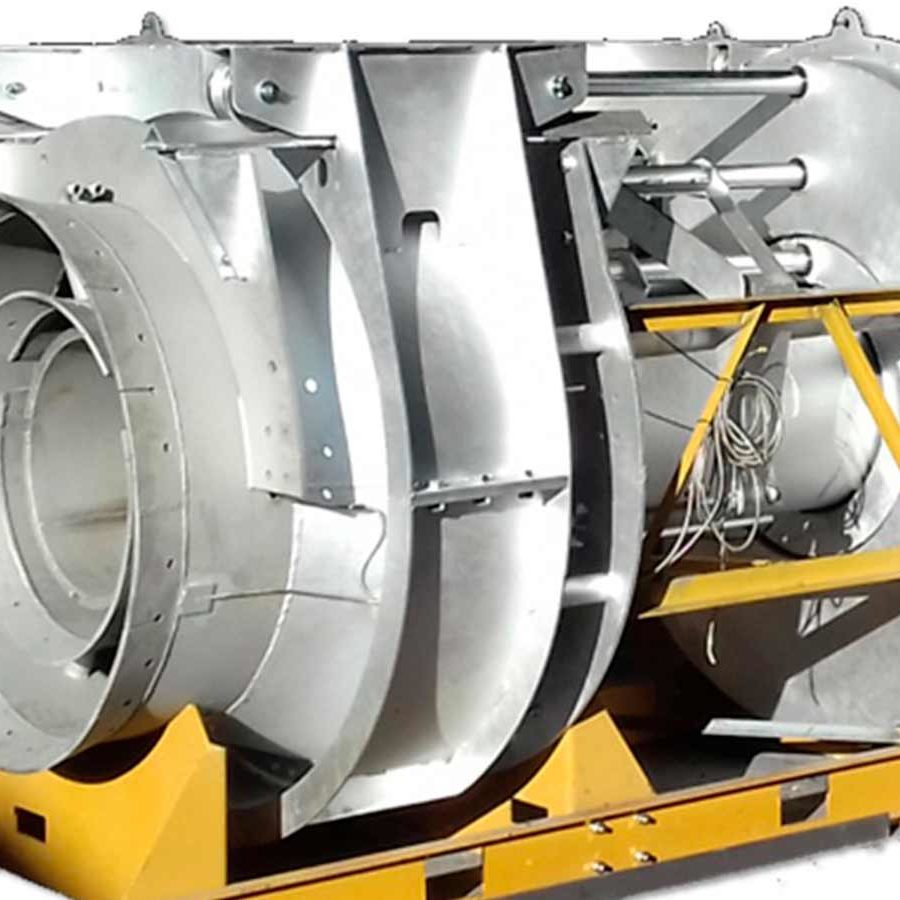

INERCO offers a broad range of Low NOx applications including Low NOx burners and OFA (Over Fire Air) systems. Design of the burners and air registers have to consider the optimal conditions of turbulence, temperature and residence time required at the burner flame to minimize NOx generation.

Design and definition of these solutions are based on vast experience in execution of combustion testing and tuning, deep knowledge of material behavior for different fuels and operating circumstances and in-house Computational Fluid Dynamic (CFD) capabilities.

Whatever are the emissions and performance requirements, INERCO can provide the right solutions executed on time and budget.

SNCR SELECTIVE NON-CATALYTIC REACTION

SNCR allows to achieve moderate NOx reductions in order to meet the stringent emission limits by environmental legislation.

Ammonia-based reagent is injected in the combustion zone to react with NOx and produce nitrogen and water. INERCO’s solution incorporates special features to enhance the operation of the system: zonal reagent injection based on local combustion conditions, closed-loop control, injection pattern based on CFD models and extensive experience.

INERCO also has a portable pilot DEMO SNCR plant for temporary testing of the technology, that allows the assurance of the technology results beforehand.

CONTACT

Diego Fernández

INERCO USAFLEXICOM-LNB

FLEXICOM-LNB technology is a retrofit in the coal pipe system to enable the installation of a SOFA (Separate Over Fire Air) section in the existing wind box arrangement, avoiding additional openings in the boiler water wall panels.

This technology is able to establish the most favorable “in-furnace fire distribution” regardless of mill in service, avoiding ”burner gap” which leads to increased NOx and carbon-in-ash. Flue Exit Gas Temperature (FEGT) control reduces detrimental effects like slagging, fouling and tube failure.

This versatile solution simultaneously addresses different targets: heat rate, emissions and operational constrains.

ENERGY STORAGE / FLEXIBLE OPERATION

INERCO offers advanced energy storage solutions for power generation (conventional and renewable), transmission, distribution and consumption.

These systems provide stability and quality to the grid by optimization and management of the generation sources.

Applications:

- Conventional power plants, combine cycles and gas turbines:

- Frequency regulation / price arbitrage.

- Operation and flexibility.

- O&M cost and emissions reduction.

- Renewables:

- Ramp rate control.

- Time shifting / load following.

- Isolated grids:

- Renewable integration.

- Voltage / frequency support.

CONTACT

Diego Fernández

INERCO USACOAL-TO-NATURAL GAS CONVERSION

There is a number of factors to be considered when evaluating the possibility of a coal to natural gas conversion project.

Fuel availability, emission regulations and remaining life of the plant must be evaluated along with the capital and operating costs. INERCO can support our clients in the configuration of the best approach.

INERCO execute coal-to-natural gas conversion projects, providing key equipment like burners, flame scanners and Boiler Management Systems (BMS).

CONTACT